- Home

- Products

- Heat Treatment Furnace

- Pit Type Electrical Heat Treatment Furnace

Pit Type Electrical Heat Treatment Furnace

Brief

The pit type furnace is cycle production furnace. Mainly used for metal parts in natural atmosphere or protective atmosphere for heat treatment.

Applicable for bright annealing tempering of carbon steel, alloy steel parts and magnetic materials in protective atmosphere, and for bright annealing of small batch of scrolling strips.

Structure

Almost pit type furnace are round type and installed in the pit for easy loading and un-loading the goods, which consist of furnace body, cover, heating element, loading basket, and temperature control system.

Main technical parameters:

| Model | Rated power (kW) | Rated temperature (℃) | Furnace hearth size (mm) | Max loading capacity (kg) | Weight (kg) |

| PQ3-65-800 | 35 | 800 | 500*650 | 150 | 1700 |

| PQ3-150-900 | 90 | 1200 | 800*1500 | 1000 | 6000 |

| Annealing heat treatment furnace | PQ3-65-800 |

| - Working chamber dimensions: 500x650 mm | |

| - Furnace: has an energy-saving dual furnace construction, made from materials such as ultralight refractory bricks, high-quality aluminum heat-resistant aluminum axitsilic. | |

| - Max temperature: 650 °C | |

| - Maximum load: 280 kg | |

| - Capacity: 35 kW (380 V / 3P source) | |

| - Oven lid: On the lid has a ventilator design with a component basket to create a forced airflow to circulate air to improve the uniformity of the temperature in the furnace | |

| - Electrical control system: with temperature control meter display number, import, recordable and automatic thing temperature, and warning of overheating | |

| Carburizing heat treatment furnace | PQ3-150-900 |

| - Overall dimensions (CxRxD): 2450x 2150x 3200 mm. | |

| - Furnace: has an energy-saving dual furnace construction, made of materials such as ultralight refractory bricks, high-quality aluminum heat-resistant aluminum axitsilic. | |

| - The lid of the oven has a large circulating fan to ensure the temperature and air in the furnace are always uniform, high carbon permeability pressure. | |

| - Working temperature: 1200 °C | |

| - 90 kW power, 380V / 3P / 50 Hz power supply | |

| - Electric control system: The oven uses a standard type of control cabinet, which has a thermo-control design that displays the number of imported and automatic record regulators, via links of compensating conductors and thermocouple, can record and auto. | |

| - Vaporize with kerosene. | |

Parts Description:

1) Body Shell: Made by steel plate and structural steel.

2) Inside of furnace cover: made by stainless steel plate.

3) Burner liner: Adopt the super light and energy conservation micropore fire-resistant heat reserving brick.

4) Aluminum silicate fiber at between burner liner and shell, and also fill full of thermo-insulating power in gap.

5) Resistance wire: Adopt the 0Cr25Al5 high resistor alloy wire installed upon brick.

6) Furnace cover: Adopt the manual lever lifter or motor-driven or hydraulic.

7) Furnace installed fan: Made by a heat-resistance stainless steel shaft and fan blade for uniform heating the work-piece.

8) Limit switch: Installed near the furnace cover for safety operation.

Controlling of the furnace temperature, automatic recording, over temperature automatic power-off protection and so on.

Main technical parameters:

| Model | Rated power(kW) | Rated temperature (℃) | Furnace hearth size (mm) | Max loading capacity (kg) | Weight (kg) |

| PQ3-25 | 25 | 1200 | 300*450 | 50 | 1700 |

| PQ3-35 | 35 | 1200 | 300*600 | 100 | 1850 |

| PQ3-60 | 60 | 1200 | 150*600 | 150 | 2650 |

| PQ3-75 | 75 | 1200 | 450*900 | 220 | 2950 |

| PQ3-90 | 90 | 1200 | 600*900 | 400 | 3700 |

| PQ3-105 | 105 | 1200 | 600*1200 | 500 | 4100 |

Remarks:

Various size furnaces can be designed and manufactured as user's needs.

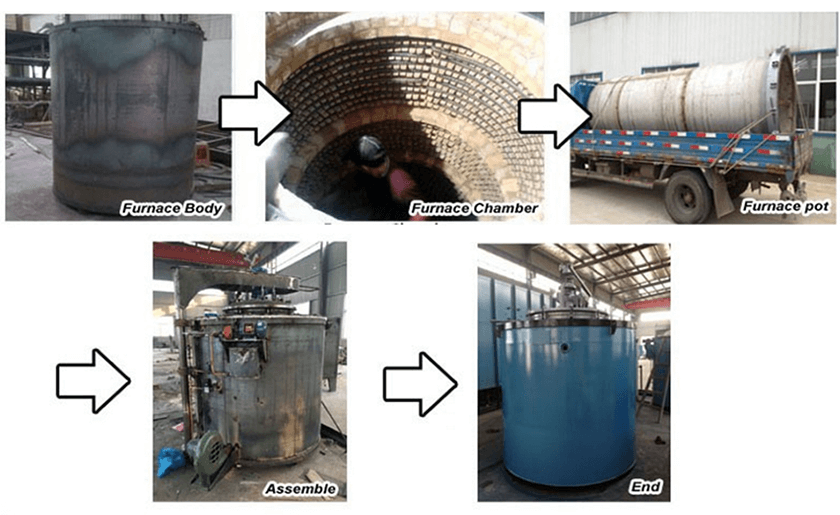

Producing Process

Characteristic:

1) Rational structure, uniform furnace temperature, small upper & lower temperature difference in working zone, especially applicable for heating and heat treatment for long axial work-piece.

2) Adopt energy-saving furnace lining, fast temperature rise, low empty furnace consumption, save more than 20% of energy compare with old product.

3) The control system can be equipped with normal control instrument or instrument with micro-processor program control according to actual need.

4) When needed during process, protective atmosphere can be fed into the furnace to realize little-oxidizing heating.

5) Each product is installed with safety interlock and over-temperature device to provide reliable and safe operation and use.

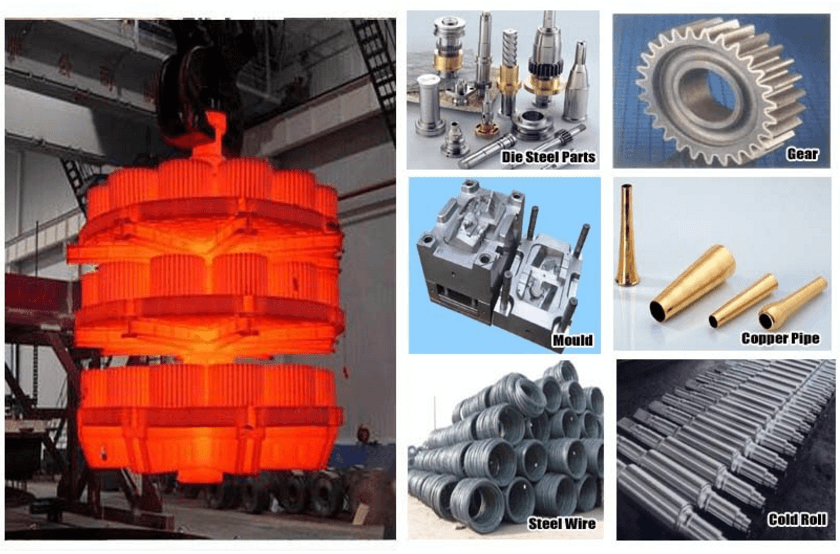

Application:

Products On Site:

Keywords

pit type heat treatment furnace, pit type annealing furnace, pit type hardening furnace, well type heat treatment furnace. pit type carburizing furnace, vacuum annealing furnace, vacuum hardening furnace

English

English Español

Español Русский

Русский Français

Français

Welcome to send your message to us