- Home

- Products

- Induction Melting Furnace

- 50kg Induction Melting Furnace

50kg Induction Melting Furnace

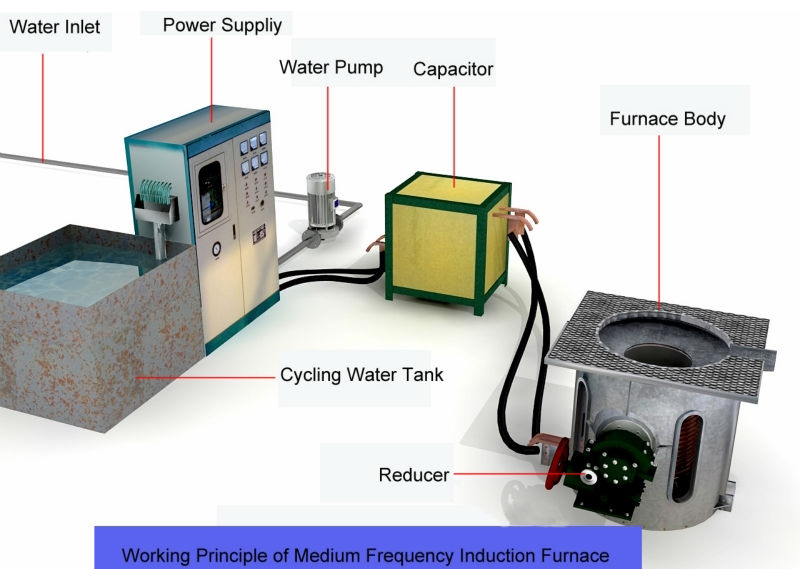

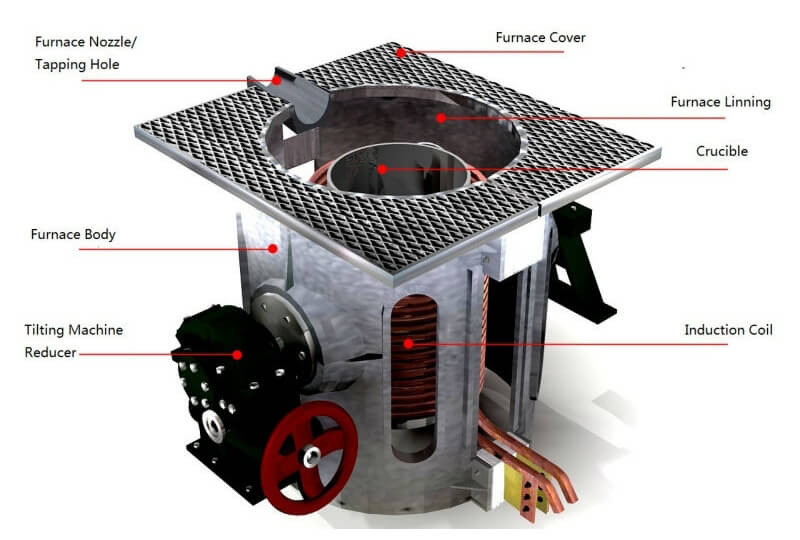

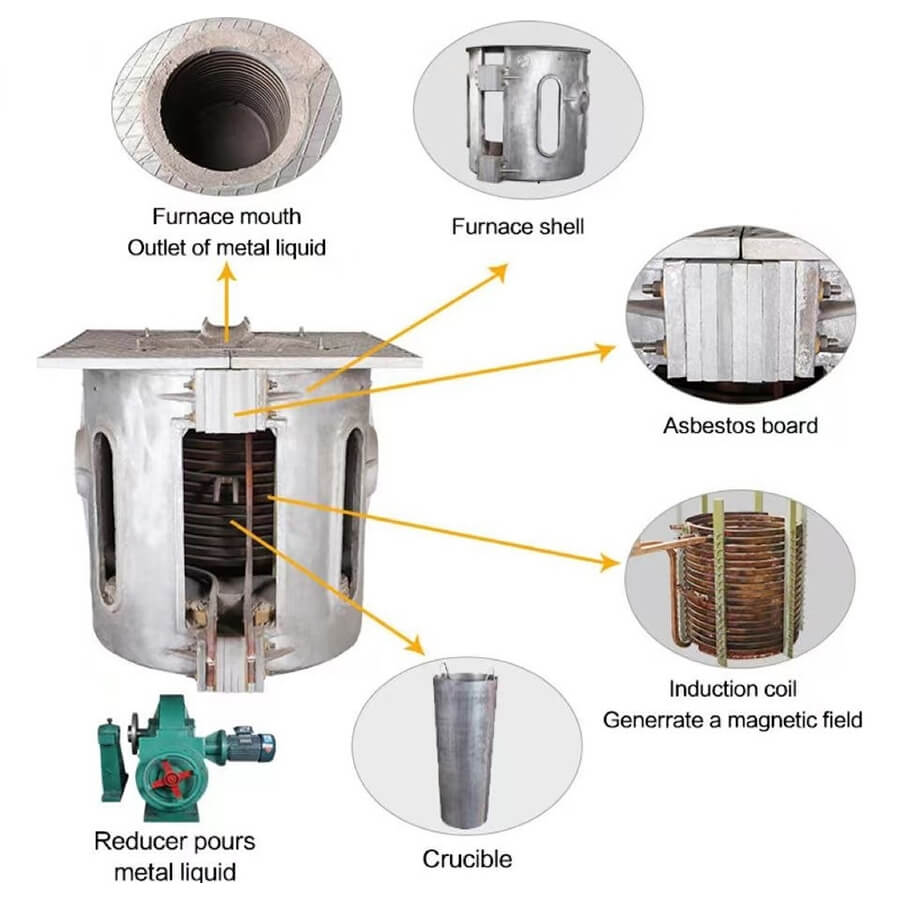

Induction furnace is an electrical furnace in which the heat is applied by induction heating of metal. Induction furnace capacities range from less than one kilogram to one hundred tons, and are used to melt iron and steel, copper, aluminum, and precious metals.

Application:

* Iron, Steel Melting

* Brass Copper Melting

* Lead Zinc Al Melting

* Gold, Sliver Melting

Heating Type:

Electrical Power

Induction heating

Features:

* Electric fuel, various capacity 0.05T-2T.

* Rapid melting speed,40-60 minutes /pot, 24 hours continuously working.

* Zero-voltage scan soft start, can start or stop anytime;

* Low energy consumption, cast iron less than 550KW.H/T.

* Less burning loss,less slag,save raw material.

* Precise temperature control to ensure the quality and capacity.

* Environmental friend l.No harmful gases and bright light.

* Easy to maintain,safe and stability, long working life.

Specifications:

| Model (Furnace capacity) | Input power 50Hz | |||

| Rated Power | Rated Voltage | Rated Current | Transformer | |

| GW-0.05T | 50 kW | 380 | 80A | 65 KVA |

| GW-0.1T | 100 kW | 380 | 160A | 120 KVA |

| GW-0.15T | 100 kW | 380 | 256A | 250 KVA |

| GW-0.2T | 150kW | 380 | 256A | 250 KVA |

| GW-0.25T | 200kW | 380 | 320A | 250 KVA |

| GW-0.35T | 250kW | 380 | 400A | 315 KVA |

| GW-0.5T | 350kW | 380 | 560A | 400 KVA |

| GW-0.75T | 500kW | 380 | 800A | 630 KVA |

| GW-1T | 750kW | 380 | 1200A | 800 KVA |

| GW-1.5T | 1000kW | 380 | 1600A | 1250 KVA |

| GW-2T | 1400kW | 750 | 1078 A | 1600 KVA |

The above data is about standard furnaces. Furnaces can be customized in different power and capacity according to customer's need.

Furnace capacity is designed based on the density of 7.8g/cm³

Product Advantages:

● Energy saving: The power efficiency is 20% less than ordinary equipment.

● High efficiency: No high-order harmonics, the highest power factor, the power factor can reach more than 95%, no reactive power compensation device and harmonic elimination device. One power supply is accompanied by one furnace for smelting and one furnace for heat preservation and refining. The utilization rate of the transformer is high, which can save half of the transformer capacity usage cost. One for two electric furnaces, two electric furnaces can be cast at the same time, and can also be continuously supplied with molten steel for casting.

● Low failure rate: The lower working voltage effectively guarantees the extraordinary stability of power devices such as thyristors.

● Safety: There are few harmonics and low power grid pollution, which effectively guarantees the safety of electricity use.

● Good starting performance: one for two electric furnaces, power is allocated at will, starting rate is 100%.

The System Include:

English

English Español

Español Русский

Русский Français

Français

Welcome to send your message to us